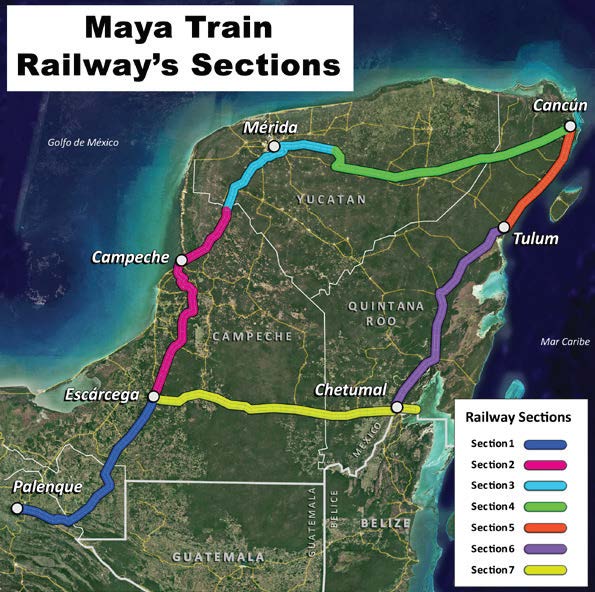

Hydroseeding was carried out in specific sections of the new “Tren Maya” railway that traverses the Yucatán peninsula in Mexico (Figure 1). The hydroseeding successfully revegetated embankment slopes to form a vegetative cover that mitigates raindrop impact and prevents erosion processes.

The railway extends for 932 miles (1,500 km) along the Yucatán Peninsula and was divided into seven sections (Figure 2). This train crosses five southeastern Mexican states of Campeche, Yucatán, Quintana Roo, Tabasco and Chiapas. The hydroseeding was conducted between December 2023 and January 2025.

The main challenges for revegetation were the type of soil, which consists of crushed limestone rock, the absence of topsoil in most of the areas and high temperatures, especially from March to June (Figure 1). A mixture of tropical grass seeds was used, specifically annual ryegrass (Lolium multiflorum) and braquiaria (Brachiaria brizantha), which were sourced from certified suppliers.

Calcareous soils with high gravel content present challenges for successful revegetation. They are structurally loose and have low-moisture retention capacity, high porosity and irregular surfaces that reduce the adhesion of applied materials. A technically efficient solution is combined paper mulch and wood fiber. Cellulose, with its fine texture, ensures more uniform coverage across the soil surface and provides high water retention. Its carbon-to-nitrogen (C:N) ratio, closest to natural source, allows good microbial activity that supports seed germination. Wood fiber contributes to the longevity of the interlocking structure that anchors effectively between coarse particles, with the amount of tackifier enhancing slope stability and erosion protection. This combination offsets the physical limitations of the substrate by integrating the absorbent properties of cellulose with the structural three-dimensional wood fiber. The blend improves the efficiency of fertilizer and mycorrhizal incorporation and enhances hydraulic performance during application. To determine the most appropriate products, the technical specifications of the main commercial brands available in the market and the Biobased certificate were reviewed to comply with the project requirements. It was concluded that the products that best met the technical requirements were High Density HMI for the cellulose component and Rainier Premium and Fiber Plus for the wood fiber component.

For the construction phase of the railway, the Mexican government divided the project into seven sections, which were awarded to major local and international construction companies. These companies contracted with Mexican contractors specialized in hydroseeding.

Two Mexican companies were responsible for the hydroseeding application across multiple sections of the railway. This article focuses on the work performed by one of these companies, Corporativo Mayra, which was involved in the final phase of the Tren Maya’s construction. This company was responsible for hydroseeding four sections covering 313 miles (505 km), with a total area of approximately 300 acres (125 ha).

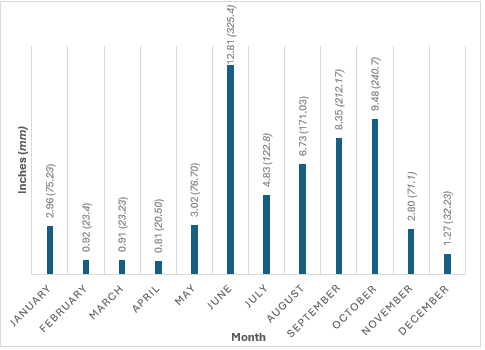

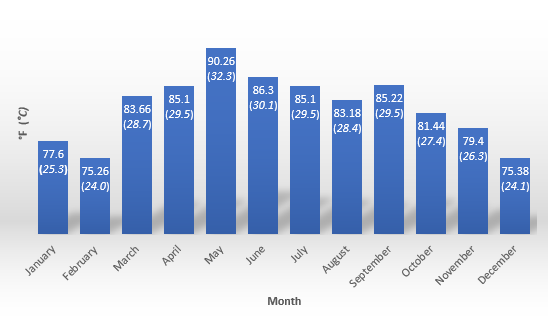

The project area is characterized by a tropical climate throughout the year, with high temperatures and a pronounced rainy season lasting half the year. The following sections provide data on average rainfall and temperature for Campeche, Quintana Roo and Yucatán, where most of the railway is located.

There is a substantial difference between the dry season (December to May) and the rainy season, which begins in mid-June and extends until November (Figure 3).

Temperature variations throughout the year are relatively small. The annual average temperature ranges for the three states go from 75.38 F to 90.26 F (24.1 C to 32.3 C) (Figure 4).

Many different hydroseeders were used to meet needs of the project.

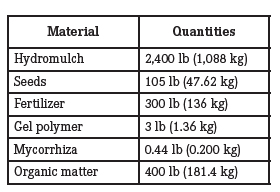

The amount of hydroseeding materials per acre applied to embankment slopes is detailed in Figure 5.

The terrain configuration along the railway varies, with embankments featuring 45-degree slopes of varying lengths and heights (Figure 6). Additionally, there are a few sections with 90-degree rocky slopes covered with three-dimensional mesh to be revegetated (Figure 7). Certain underpasses feature structures resembling gabion walls, locally known as “Tai walls,” which also required hydroseeding.

During the hydroseeding application, logistical challenges arose, primarily regarding water availability, which was managed by the construction companies involved in the project. The hydroseeding sections lacked nearby surface water sources, such as rivers, small creeks or lakes, and water access points were limited and often distant. Moreover, water tankers were also in demand for construction activities at the same time. To address this issue, coordination was established with contractors to ensure the necessary daily water supply and, in some cases, implement a night shift to apply hydroseeding (Figure 8).

The selected grass seeds were tropical, noninvasive, non-aggressive, certified and commercially available. Annual ryegrass exhibits rapid germination of six to nine days and provides quick surface coverage due to its fast growth. Braquiaria, on the other hand, germinates within 10 to 12 days and grows more slowly until it develops additional leaves. Once annual ryegrass completes its life cycle in 10 to 12 months, it decomposes, enriching the soil with organic matter.

Monitoring visits were conducted to assess germination rates. Initial evaluations indicated lower-than-expected germination due to high temperatures causing excessive evapotranspiration, leading to rapid soil drying. Post-seeding irrigation was managed by the construction contractors. During evaluations, findings were shared with them to improve irrigation practices. The absence of significant rainfall in the early months further complicated the situation and prompted recommendations for early morning or evening watering to retain soil moisture longer. In some cases, nighttime hydroseeding was carried out using equipment mounted on a railway platform.

Frequent rainfall from mid-June through late September significantly improved germination rates, both in previously seeded areas with lower initial germination and in newly hydroseeded zones. In areas with low germination, agreements were made with clients to reapply hydroseeding to ensure uniform vegetation coverage.

When the rainy season began, the tackifier in the hydroseeding mix was increased to enhance soil adhesion. This approach successfully prevented runoff losses on embankments. In the Tulum section, coconut fiber blankets were installed after hydroseeding (Figure 9), while in the Playa del Carmen section, hydroseeding was applied over pre-installed coconut fiber mats.

In rocky areas and Tai walls, a two-layer application was implemented:

• The first layer consisted primarily of organic matter and tackifier.

•This was followed by a second layer containing mulch, seeds, fertilizer, tackifier and polymer gel.

Germination and grass growth on embankment slopes, which constitute 95% of the hydroseeded areas, were successful, given the challenging soil conditions. Additionally, the organic matter and fertilizers improved soil quality, which promoted the emergence of native plant species. Figure 10 shows a before-and-after comparison.

Steeper cut slopes with three-dimensional mesh showed lower germination due to their vertical nature and lack of permeable soil structure, which increased evapotranspiration and required more frequent irrigation. On Tai walls, germination and growth were more successful, particularly during the rainy season, although growth declined as rainfall decreased.

Throughout 2025, ongoing monitoring of hydroseeded areas will be conducted to analyze vegetation succession dynamics, as native species are expected to gradually replace the planted grasses. This information will be presented in a future article.

Conclusion

The hydroseeding application along the Maya Train corridor stands as a milestone in large-scale revegetation work, for Latin America especially, in geographic scope and technical execution. Carried out across approximately 300 acres (more than 125 hectares) under extremely challenging conditions — poor, rocky soils with little to no topsoil, high temperatures, a specific rainfall window and limited surface water access — this project demanded adaptive strategies and operational innovation. From selecting fast-germinating, non-invasive tropical grasses to coordinating irrigation logistics and adjusting application techniques based on slope type and seasonality, the work combined biological precision with logistical agility. The successful establishment of vegetation in such an environment not only achieved the project’s erosion control goals but also created a replicable framework for similar efforts across the region. As a reference case, it offers valuable insights for future infrastructure projects facing analogous constraints in tropical climates, degraded soils and remote locations throughout Latin America.

About the Experts

• Moisés A. Cavero is the director for Latin America at Hamilton Manufacturing Inc. (HMI). He has more than 30 years of experience in erosion control and revegetation. He has worked on projects in Ecuador, Bolivia, Mexico, Panama and Peru.

• Miguel Tapia-Mendoza is CEO of Corporativo Mayra in Mexico. He has extensive experience with comprehensive solutions for environmental care, environmental consulting, erosion control, hydroseeding, reforestation, landscaping and nurseries.

• Víctor Lazcano Cornejo is a civil engineer and serves as operations manager of Corporativo Mayra. He has 25 years of experience in industrial gardening, landscaping, irrigation systems and manual and hydroseeding revegetation.

• Juan M. Vázquez Donnadieu is the founder of Preslam Concrete, Dovac and Vadone Construction. He is an architect and businessman. He joined Corporativo Mayra in 2023 as the administration director. He participated in the Maya train project, reforestation projects and the Pachuca-Huasca highway remodeling.

• Carlos F. Garcia is a forestry engineer specializing in environmental management in mining, energy, and oil and gas projects. Garcia has more than 30 years of experience working in bioremediation of disturbed areas. He is a pioneer in hydroseeding in Peru.