Call for innovation 1 / Peer Reviewed

TerraTex Bio Fence reinvents erosion control fencing to reduce plastic waste

By Derek McMahan, Senior Product Manager, Hanes Geo Components

Check Dams Stand the Test of Time

In today’s construction and environmental industries, sustainability is no longer a buzzword; it’s a mandate. As climate change, resource depletion, and waste accumulation continue to challenge global ecosystems, the demand for innovative, eco-conscious solutions has never been greater.

Among the most promising developments in erosion control is the TerraTex® Bio Fence, a bio-based alternative to traditional silt fences that’s reshaping how professionals think about sediment management and site protection.

Developed by Hanes Geo Components, a division of Leggett & Platt Inc., TerraTex Bio Fence offers a compelling solution to one of the most overlooked contributors to construction waste: petroleum-based plastic silt fencing. By replacing petroleum-based plastic with natural coconut-burlap fibers, TerraTex Bio Fence is helping contractors, engineers, and environmental professionals meet environmental sustainability goals without compromising performance.

The Problem With Silt Fences

Silt fences are a staple on construction sites for preventing sediment runoff and protecting nearby bodies of water. Most are made from polypropylene, however—a petroleum-derived plastic that usually is neither biodegradable nor recyclable. Once a project ends, silt fences are typically discarded, contributing to the millions of pounds of plastic waste that enter landfills each year.

A standard 100-foot run of silt fence weighs between 40 and 60 pounds. With an estimated 100,000 construction sites using an average of 1,000 feet of silt fence annually, the U.S. alone could be generating 50 million pounds (25,000 tons) of silt fence waste per year. This staggering figure highlights the urgent need for alternatives that reduce environmental impact while maintaining regulatory compliance.

A Strategic Solution

TerraTex Bio Fence addresses this challenge head-on. It’s constructed from a spunbond, nonwoven geotextile made of polylactic acid (PLA)—a polymer derived from renewable resources including corn starch—and natural coconut burlap fibers. This combination results in a product that is free of petroleum-based materials, UV resistant, and durable enough for active construction sites.

Unlike traditional silt fences that persist in the environment for extended periods of time, TerraTex Bio Fence fabric breaks down naturally over time. PLA transforms a renewable crop into a compostable product as an alternative to petroleum-based silt fences. Bio Fence also includes jute fibers, which likewise naturally decompose into soil within a few years, making the product highly ecofriendly.

The manufacturer of the PLA used in Bio Fence says it typically composts within 90 to 180 days in an industrial environment; it is currently undergoing additional biodegradability testing at TRI. Time to compost in a landfill is dependent on outside factors such as temperature, but what seems clear is that Bio Fence reduces long-term environmental impact when compared to petroleum-based products, making it an ideal choice for projects in sensitive ecological zones or areas governed by strict environmental regulations.

Meeting Performance Standards

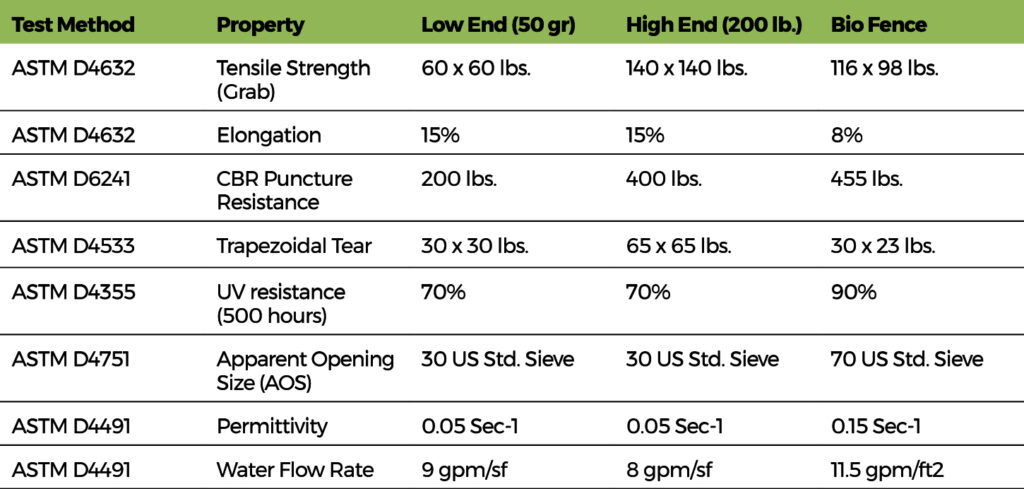

One of the most common concerns about bio-based products is whether they can match the performance of their petroleum-based counterparts. Compared to other products used in silt fence applications, TerraTex Bio Fence meets or exceeds the current standards of petroleum-based products. The product meets a range of rigorous ASTM standards (Table 1).

These metrics demonstrate that the product is not only an environmentally responsible alternative, but also structurally sound. It can withstand heavy equipment, variable weather conditions, and high water flow rates, making it suitable for a range of construction and landscaping applications.

Environmental and Regulatory Benefits

By eliminating polypropylene and other petroleum-based plastics, TerraTex Bio Fence delivers erosion control with less environmental disruption.

Under the National Pollutant Discharge Elimination System (NPDES), a program authorized by the Clean Water Act, construction activities that disturb one acre or more must implement erosion and sediment control measures to prevent polluted stormwater from entering U.S. waterways. One of the most common tools used to meet these requirements is the silt fence.

As environmental regulations tighten across local, state, and federal levels, products such as TerraTex Bio Fence can help contractors stay ahead of compliance requirements. They offer a proactive approach to meeting EPA stormwater permit standards under the NPDES program, while also aligning with corporate sustainability goals.

Industry Adoption and Momentum

TerraTex Bio Fence is gaining traction among a diverse range of stakeholders, including:

- Contractors seeking a low-cost, environmentally conscious erosion

control solution; - Environmental consultants focused on minimizing site impact; and

- State Departments of Transportation (DOTs) looking for scalable, more sustainable infrastructure solutions than traditional silt fencing.

Its adoption reflects a growing industry trend toward green infrastructure and responsible land development. “We’ve channeled our innovation into developing an alternative that answers the call for polypropylene-free materials while still meeting the outstanding performance standards our products are known for,” says John Dowdell, Hanes Geo Components president.

Looking Ahead

As public awareness grows and environmental regulations become more stringent, the construction industry must evolve. Products like TerraTex Bio Fence represent a new generation of erosion control—one that balances performance with responsibility. They signal a shift not just in materials but in mindset.

In a world where every pound of plastic matters, choosing bio-based solutions isn’t just smart, it’s essential. TerraTex Bio Fence proves that sustainable engineering and strength can coexist, offering a blueprint for the future of erosion control.

About the Expert

Derek McMahan, MBA, is a senior product manager with Hanes Geo Components. He has more than 10 years of experience with erosion and sediment control.

References

- BigRentz. (2024). 24 Construction Waste Statistics & Tips to Reduce Landfill Debris. bigrentz.com/blog/construction-waste-statistics?srsltid=AfmBOopH3XXBHW7LUY2W2z0cZgUbcHDFhruC9Zy6M8OE761gQ0_7mcw9

- United States Environmental Protection Agency. Stormwater Best Management Practices. Silt Fences. EPA.gov. epa.gov/system/files/documents/2021-11/bmp-silt-fences.pdf