Linear construction, such as the highway projects managed by Departments of Transportation (DOTs) in the United States, presents a unique set of stormwater management challenges. Due to limited right-of- way (ROW) and numerous off-site discharge points, these projects often lack the space for traditional stormwater controls like large sediment basins or natural buffers.

Linear construction projects typically involve extensive clearing and grading, which

increases the risk of erosion and sediment-laden runoff. Although best practices such as

minimizing disturbance, phasing work and improving site communication can help, some

areas will inevitably remain exposed during active construction. In these areas, it is crucial

that erosion and sediment control practices are effective.

In recent years, research has been conducted to provide performance-based design, but it has largely relied on large-scale, controlled research settings. The goal of this work was to see how the designs translated to field conditions. To answer that question, the Iowa DOT sponsored a large-scale field study along a 12-mile (19-km) stretch of U.S. Highway 30 in Tama County, Iowa, United States. The project involved replacing a two-lane road with a new four-lane highway, complete with a median and shoulders (Cover photo). Researchers focused on three primary areas — perimeter control, ditch checks and detention practices — as researchers and the technical advisory committee decided these practices were potentially the most impactful for sediment control due to their frequency of use. The evaluation period for perimeter control and ditch checks occurred across five months and experienced a cumulative rainfall of 12 inches (30.5 cm). Detention practice monitoring occurred over two construction seasons, but it was paused during freezing conditions to avoid damage to automated water sampling and monitoring instruments. Soil samples from the site indicated a lean clay with sand (CL-SC), according to the Unified Soil Classification System.

Perimeter Control

In total, six silt fence designs were evaluated. The standard design used woven geotextile fabric trenched into the ground or sliced in and attached to t-posts spaced 8 feet (2.4 m) apart. However, t-post deflection, undercutting and geotextile tearing were regularly documented as problem areas for this configuration. Modifications were suggested to

improve these problem areas and included:

- Reducing post spacing to 5 feet (1.5 m)

- Adding wire reinforcement

- Offsetting the geotextile fabric 6 inches (15

cm) from the t-post line before keying into

the ground - Evaluating trenching vs. slicing methods

Weekly inspections, including aerial imagery acquired by unmanned aerial systems (UASs), revealed that wire reinforcement and reduced spacing improved structural integrity. However, contractors found wire reinforcement more difficult to install. As a result, reducing post spacing was recommended as the most practical improvement. Also, the offset was recommended, as it had no additional cost associated and seemed to minimize dislodgement of the geotextile from the ground over time.

Ditch Checks

Silt fence and wattles were evaluated as ditch checks. Evaluation of the ditch checks included structural integrity, sedimentation and impoundment. The structural integrity was visually monitored through weekly photo inspections and channel surveying. Sedimentation was measured using channel surveying and aerial imaging.

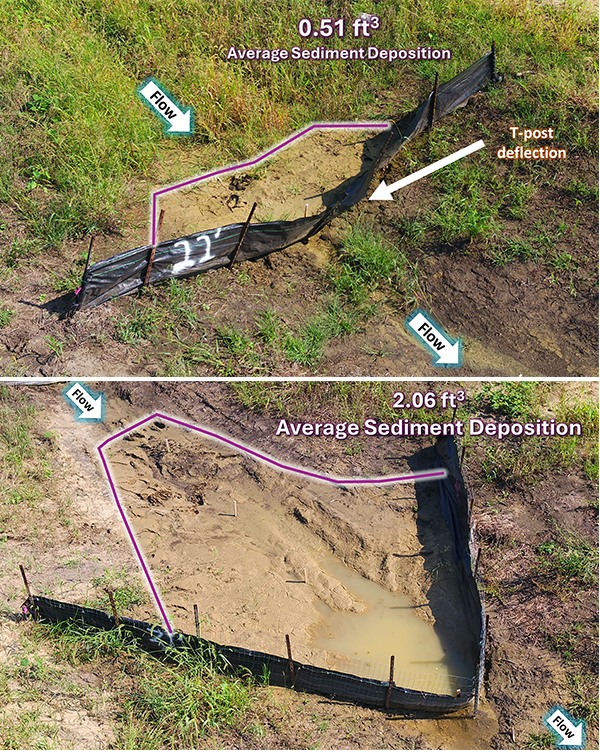

The standard silt fence ditch check design used 4-feet (1.2-m) post spacing and geotextile fabric trenched or sliced into the ground.

Modifications included:

- V-line installation with a dewatering weir

- 3-feet (0.9 m) post spacing

- Wire reinforcement

- 6-inch (15-cm) offset

The most effective configuration featured all four modifications and captured four times more sediment than the standard. However, contractors noted that the V-line installation was difficult due to the required 45-degree slicing angle. The standard and modified installations are shown in Figure 2.

and wire reinforcement

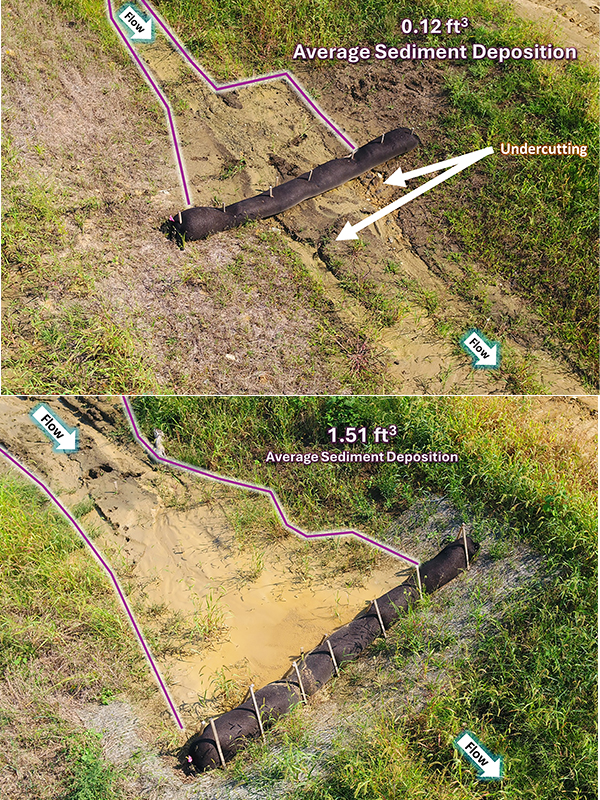

The standard wattle ditch installation specified that wattles should be installed perpendicular to the flow direction channel and staked through the media every 2 feet (0.6m). Modifications included:

- A natural fiber underlay

- Pinning the wattle to the ground

- A-frame staking to reduce damage and

buoyancy

The modified installation increased sediment capture by 12 times when compared with the standard design. The Iowa DOT has since adopted this modified wattle design into its standard practices. The standard and modified installations are shown in Figure 3.

Sediment Basin

Additionally, the research team identified a unique sediment basin design that used an in-channel approach to create a detention environment. To achieve this, an earthen berm was constructed across the drainage channel along the shoulder. A riser pipe was installed through the berm to allow for controlled dewatering, and an auxiliary spillway was cut and armored with erosion stone. The team monitored a single basin and a series of two basins to evaluate turbidity reduction.

The site soil was fine, with a d50 0.025 mm, and, therefore, required settling times that exceed the residence time of water detained in the basin. Ultimately, the results showed

negligible turbidity reduction over two construction seasons. However, the in-channel design was considered an innovative solution for managing stormwater within the limited ROW that is typical of linear construction sites. As a result, several design modifications were recommended for further testing, including geotextile stabilization, surface dewatering using a skimmer, flow baffles to distribute flow across the width of the basin and the addition of an upstream forebay. Although these modifications were not tested on-site, they prompted the initiation of a separate project focused on controlled, large-scale testing of basin components.

Unlike lab studies, field research captures the messy realities of construction: contractor installation practices, upstream activity, unpredictable weather and real-world maintenance (or lack thereof). No maintenance was performed during the study, which offered rare insight into the longevity of erosion and sediment control (E&SC) practices. The use of an Unmanned Aerial System (UAS) also proved invaluable by providing aerial perspectives after storm events, which would be difficult to capture otherwise. This research highlights the importance of adapting E&SC practices to the unique constraints of linear construction. By testing and refining designs in the field, DOTs can make data-driven decisions that improve water quality, reduce maintenance and support infrastructure development. Even small changes, such as adjusting post spacing or adding a fiber underlay, can make a big difference when tackling stormwater challenges on linear sites.

For more information, read: Schussler JC, Kazaz B, Perez MA, et al. 2021. Field Evaluation of Wattle and Silt Fence Ditch Checks. Transportation Research Record, 2675:281-293. Or visit the fact sheet at bit.ly/45FDF2R.

About the Expert

• Jaime C. Schussler, Ph.D., PE, CPESC, is an assistant professor, School of Civil and Environmental Engineering, Oklahoma State University. She received her Ph.D. from Auburn University, where she conducted research for the Iowa DOT. She is a member of the International Erosion Control Association (IECA) Standards and Practice Committee and South-Central Board.

• Billur Kazaz, Ph.D., PE, CPESC, is an engineer at Geosyntec Consultants, Kennesaw, Georgia, United States. Kazaz focuses on erosion and sediment control, construction stormwater management, construction site UAS and GIS. She is a member of the IECA Editorial Review Board and IECA Southeast Board.

• Michael A. Perez, Ph.D., PE, CPESC, is the Brasfield & Gorrie associate professor, Department of Civil and Environmental Engineering, Auburn University. Perez is the director of Auburn’s Stormwater Research Facility, which provides interdisciplinary research, product evaluation and hands-on training.